Driver Vehicle Standards Agency

In this section

- 4.1.1. Presence, condition and operation

- 4.1.2. Headlamp alignment

- 4.1.3. Switching

- 4.1.4. Compliance with requirements

- 4.1.5. Levelling devices

- 4.1.6. Headlamp cleaning devices

4.1.1. Presence, condition and operation

4.1.1. Presence, condition and operation

You must test all mandatory headlamps.

Mandatory headlamps are a matched pair of main beam headlamps and a matched pair of dipped-beam headlamps. These can be separate or a single pair of headlamps.

Lamps are matched if they:

- emit light of substantially the same colour and intensity

- are the same size and shape that they are symmetrical to each other

You do not need to test headlamps on vehicles that are not fitted with position lamps, or have such lamps permanently disconnected, painted over or masked, that are:

- only used during daylight hours, and

- not used at times of seriously reduced visibility

Vehicles first used before 1 January 1931 do not need headlamps.

Buses first used before 1 October 1969 only need one headlamp. If 2 are fitted, neither the main beam or dipped beams need to be a matched pair.

You must assess damaged or repaired lamps for security, colour, light output and durability.

Tricycle and quadricycle headlamps must be:

- mounted centrally - if theres only one lamp

- mounted symmetrically about the centre - if theyre adjacent to another lamp, such as theres one dipped beam lamp and one main beam lamp

- mounted symmetrically - if theres 2 lamps

The following must have a pair of main beam headlamps and a pair of dipped beam headlamps can be separate or a single pair of headlamps:

- tricycles and quadricycles with a maximum width over 1,300mm

- motorcycle derived tricycles with a maximum width over 1,700mm

Tricycles and quadricycles classed as mopeds do not need a main beam headlamp.

A light source means any bulb, LED or other means of emitting light.

| Defect | Category |

|---|---|

| (a) A headlamp: (i) with up to light sources not functioning in the case of LED (ii) missing, inoperative or more than not functioning in the case of LED | Minor Major |

| (b) Headlamp reflector or lens: (i) slightly defective (ii) seriously defective or missing | Minor Major |

| (c) Lamp not securely attached | Major |

4.1.2. Headlamp alignment

You must inspect all dipped beam headlamps fitted.

The type of headlamp will determine whether the aim must be checked on dipped or main beam (see Diagrams 1, 2 and 3).

A flat top or other alternative headlamp dipped beam pattern is acceptable as long as all of the beam upper edge, including any peak is contained within the appropriate tolerance band.

Its acceptable for masks or converter kits to be fitted to right hand dip headlamps to temporarily alter the lamp for use in the UK by removing the beam kick-up to the right.

If drivers beam aim controls are fitted, you should test the beam aim without altering the control setting. If this would result in failure for beam aim being too low, you should re-check the beam aim with the control set at its highest position.

On vehicles with hydro-pneumatic suspension systems, its necessary to have the engine running when checking headlamp aim.

To check the aim:

Position the vehicle on the designated headlamp aim standing area.

Align the headlamp aim testing equipment to the vehicle in accordance with the manufacturers instructions.

Determine the appropriate headlamp beam image and its aim (see Diagrams 1, 2 and 3).

For complex lens systems - meaning those that have more than one lamp behind a single lens - make sure the test equipment is aligned exactly on the centre of the dipped beam pocket.

You must not carry out repairs during an MOT test, but you can make minor adjustments to the headlamp aim.

European type - check on dipped beam

European type lamps have one of the following:

- an asymmetric dipped beam pattern with

- a horizontal cut-off on the right

- a wedge of light above the horizontal towards the left, known as the kick up

- lens may have European approval mark

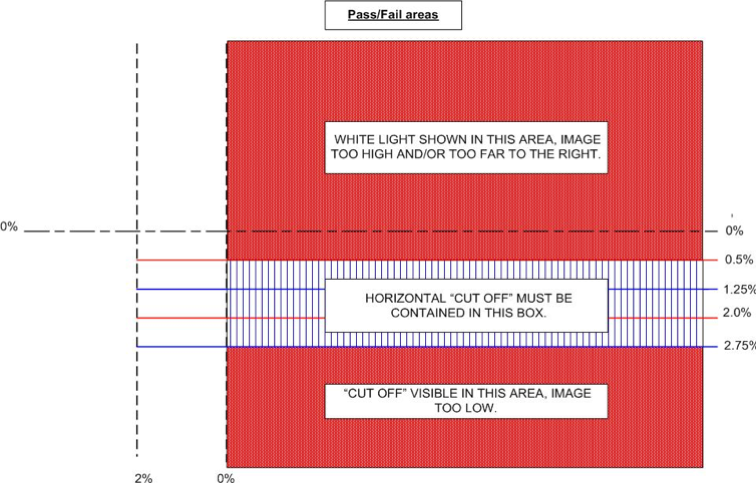

For European type lamp to pass, you must make sure that:

- beam image kick up is visible on the screen, unless it has been masked or it has a flat top beam pattern

- for headlamps with centres at 850mm or less from the ground, the beam image horizontal cut-off is between the 0.5% and 2.75% horizontal lines

- for headlamps with centres more than 850mm from the ground, the beam image horizontal cut-off is between the 1.25% and 2.75% horizontal lines

- white light does not show in the zone formed by the 0% vertical and 0.5% horizontal line

Diagram 1. Criteria for European beam headlamp aim

British American headlamp - check on main beam

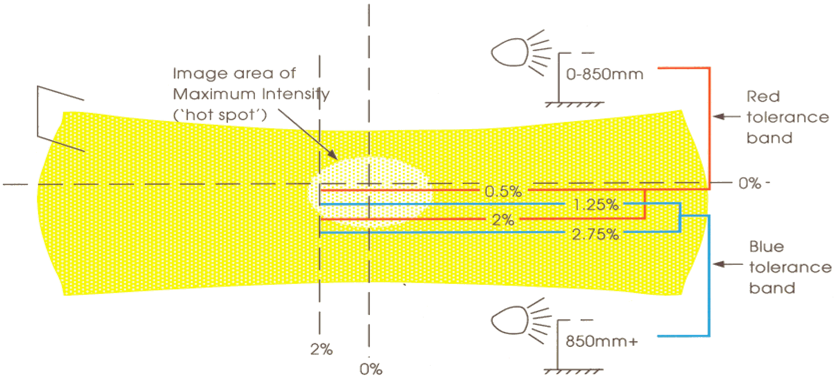

British American type headlamps are checked on main beam if they have an asymmetric main beam pattern with a central area of maximum intensity, known as a hot spot.

The generally also have a circular lens marked with a figure 1 followed by an arrow indicating the direction of dip.

You must fail a British American type lamp if its hot spot centre is any of the following:

- above the horizontal 0% line

- below the horizontal 2% line for headlamps with centres at 850mm or less from the ground

- below the horizontal 2.75% line for headlamps with centres more than 850mm from the ground

- to the right of the vertical 0% line

- to the left of the vertical 2% line

For a British American type lamp to pass, you must also make sure the brightest part of the image moves downwards when the lamp is dipped.

Diagram 2. Main beam image

British American headlamp - check on dipped beam

Check British American headlamps on dipped beam if they have:

- an asymmetric dipped beam pattern with a flat-topped area of high intensity extending above and parallel with the horizontal 0% line on the nearside

- a circular lens marked with the figure 2 it might also have an arrow showing the direction of dip

You must fail this lamp if the upper edge of the hot spot is:

- above the horizontal 0% line

- below the horizontal 2.75% line

You must fail this lamp if the right-hand edge of the hot spot is:

- to the right of the vertical 0% line

- to the left of the vertical 2% line

Diagram 3. Dipped beam image

Not tested or Unable to be tested must only be used where it becomes apparent during the test that the particular item cannot be tested, and this could not have been identified prior to starting the test. The reason for selecting the failure must be included in the additional information box.

| Defect | Category |

|---|---|

| (a) The aim of a headlamp is not within limits laid down in the requirements | Major |

| (b) Headlamp aim unable to be tested | Major |

| (c) Beam image obviously incorrect | Major |

4.1.3. Switching

Dipped or main beam headlamps must immediately light up when theyre switched on (depending on the position of the dip switch).

Headlamps must switch immediately between main beam and dipped beam when you move the dip switch.

Moving the dip switch must do one of the following:

- extinguish all main beam headlamps and leave on at least one pair of dipped-beam headlamps

- deflect the main beams to make them dipped beams

Dipped beam headlamps can remain on or switch off when main beam is selected.

Headlamps are not needed on vehicles first used