Driver Vehicle Standards Agency

class="gem-c-govspeak govuk-govspeak govuk-!-margin-bottom-0">

The types of load in this section are listed in alphabetical order.

Abnormal loads?are generally larger or heavier than ordinary plant equipment or machinery. They can cause significant harm to the driver and other road users if they become detached from the vehicle.

Operators should make a separate plan for every abnormal load movement and make sure the load is secured appropriately because of the increased risk.

You must take reasonably practicable steps to secure abnormal loads.

The most effective way to do this is with a combination of physical restraints to movement such as lashings use chains instead of straps for heavy loads and:

- bulkheads

- chocks or dunnage

- cradles

The load must be stable on the load bed without lashings.

You must not:

- attach more than one lashing to a single attachment point

- loop lashings through or around attachment points and then hook the lashing onto itself this can damage the lashing and reduce its effectiveness

If the vehicle does not have a headboard and there is no reasonably practicable way of fitting a physical barrier to stop the load moving forward, you must use additional lashings, preferably chains, to achieve an equivalent level of safety. You may also need to use friction matting or a high-friction floor to reduce the risk of movement.

Wheeled or tracked equipment

If the load bed does not adequately support the equipments wheels or tracks, you should either:

- make sure the body is supported instead

- rest the equipment on timbers or something similar

Operator and consignor responsibilities

Operators and consignors should:

- carefully plan each abnormal load movement

- make sure that the abnormal load is secured appropriately

- agree what loading and securing scheme to use

- give any drivers or loaders that will secure the abnormal load appropriate training on how to load and secure the load

Operators and consignors must work together to provide clear instructions to drivers on:

- suitable methods of loading and securing for each load type

- how to check tension in the lashings at regular intervals

- what to do if the load shifts during the journey

They must ensure that the load complies with?Road Vehicles Lighting Regulations 1989 (SI No 1796)?if it obscures:

- obligatory lights

- re?ectors

- rear markings

- registration plates

Check the rules for abnormal load vehicles and their escort vehicles.

You must load hay and straw bales so that their weight is fully supported by the load bed. You must make sure the stacks are stable before you secure them.

You must secure hay and straw bales carried on vehicles or open trailers using either:

- at least one lashing strap that passes over the top of eachstack of bales or individual bale, and additional strapping at the front and the rear of the load

- rated nets or sheets, straps, and chains

- strapping over the top of an empty pallet (or similar items that spread the forces) placed on top of the bale to help distribute the force of the straps

- strapping to secure bales that sit above the sides of the trailers with hydraulic operated bale securing frames or clamps

Wider lashing straps can help to spread the force over the load, which can prevent it being damaged or cut into by traditional lashing straps.

You must make sure that hay or straw does not become loose during transport and cause a hazard to other road users. The looser the bale, the more likely it is to blow off the vehicle.

If you have diagonal straps at the rear of the load in addition to straps over the top of the bales, remove these first during unloading before removing the straps that pass over the top of the bales.

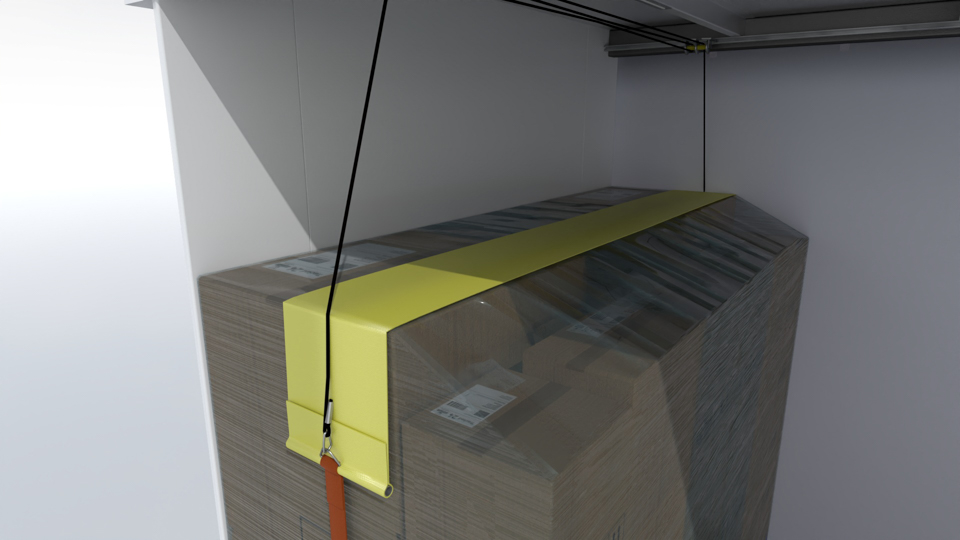

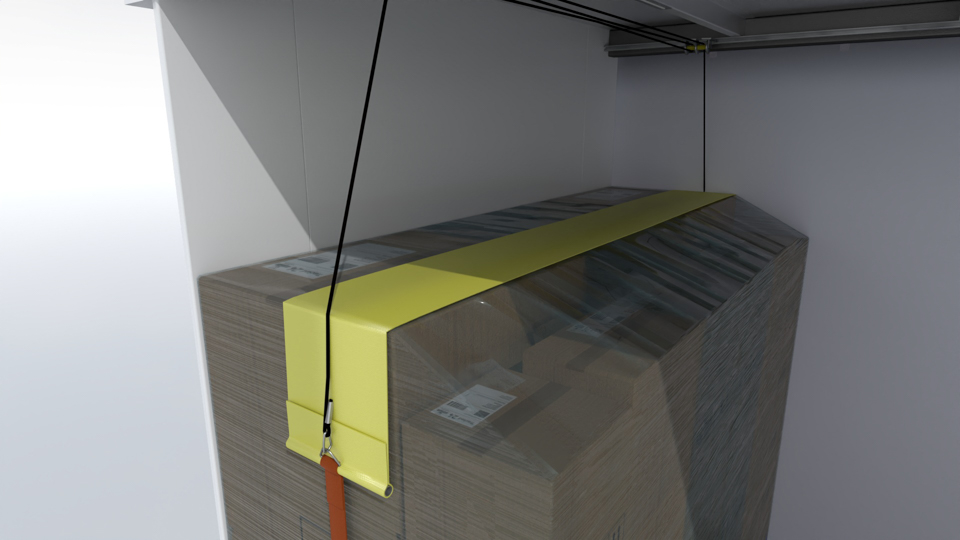

When transporting boxes you should:

- place them against the headboard or within 30cm of it if possible, and secure them using lashing ratchet straps if carried on open trailers

- use additional strapping at the front and rear if the boxes are stacked

- not stack boxes more than 3 on top of each other

You should secure bulk bags by:

- using suitable nets or sheets

- strapping the load to the vehicle through the bag lifting eyelets or lifting pocket

- strapping over the top of an empty pallet placed on top of the bag to distribute the force of the straps

- using wider lashing straps to distribute the force over the load

You must:

- use at least one strap per row

- cover any open bags if the securing method does not prevent the contents spilling or blowing out

Related Articles

Comments

Write a Comment

Ministerial Departmental News

- PM's Office, 10 Downing Street

- Cabinet Office

- Department for Business, Innovation and Skills

- Department for Communities and Local Government

- Department for Culture, Media and Sport

- Department for Education

- Department for Environment, Food and Rural Affairs

- Department for International Development

- Department for Transport

- Department for Work and Pensions

- Department of Energy and Climate Change

- Department of Health

- Foreign and Commonwealth Office

- HM Treasury

- Home Office

- Ministry of Defence

- Ministry of Justice

- Northern Ireland Office

- Scotland Office

- Wales Office

- See all departments