Uk Space Agency

- the Aqualunar Challenge is a 1.2 million international prize funded by the UK Space Agencys International Bilateral Fund and delivered by Challenge Works

- today, it is awarding 300,000 to UK teams developing technologies to purify ice frozen in the Moons soil to make human habitation on the lunar surface viable

- diamond encrusted filtration units, concentrated sunshine and ultrasound purification are in the running to win the Aqualunar Challenge

Ten cutting-edge teams of innovators, engineers and scientists, that are developing new technologies to provide a permanent crewed base on the Moon with reliable water supplies, have been named finalists in the Aqualunar Challenge.

The Aqualunar Challenge is part of a 1.2 million international prize funded by the UK Space Agencys International Bilateral Fund and delivered by Challenge Works experts in designing and running innovation challenge prizes.

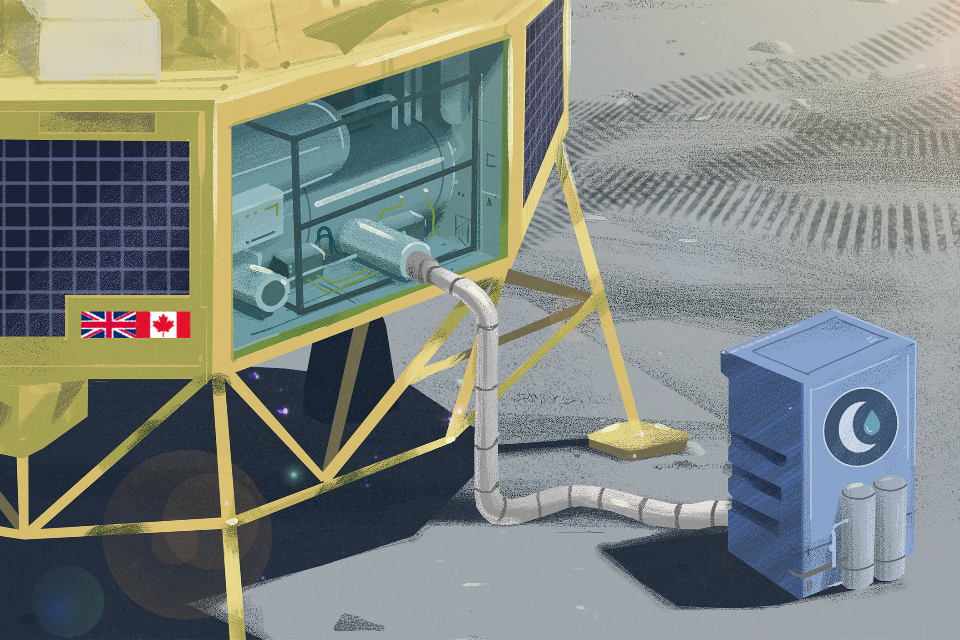

The challenge is a collaboration with the Canadian Space Agency (CSA) and Impact Canada. The UK track of the challenge is awarding UK-led finalist teams 30,000 each to develop their technologies, before a winner and runners-up are announced in Spring 2025.

Around the lunar south pole, its estimated that 5.6% of the soil (regolith) is water frozen as ice. For a permanent crewed base on the moon to be possible, astronauts will need a reliable supply of water for drinking and growing food, as well as oxygen for air and hydrogen for fuel.

If the lunar ice can be successfully extracted, separated from the soil and purified, it makes NASAs goal of establishing a base by the end of the decade viable. The Artemis campaign, as it is known, is supported by the UK Space Agency through its membership of the European Space Agency.

Paul Bate, CEO, UK Space Agency, said:

The ambition to build a sustainable human presence on the Moon through the NASA-led Artemis Missions will only succeed if we have ways of generating a reliable supply of clean water. The Aqualunar Challenge showcases a range of innovative ideas from UK teams and individuals to tackle this challenge, while strengthening ties with our Canadian partners.

Space exploration pushes our knowledge to its limit and spurs innovation, resulting in new products and services that can also benefit citizens on Earth. Congratulations to all the finalists who will now go on to develop their ideas further.

Explaining the importance of these new technologies, UK Space Agency reserve astronaut and chair of the Aqualunar Challenge judging panel, Meganne Christian, said:

To sustain a permanent crewed base on the Moon over years and decades, astronauts will need a reliable water supply, which we can also use to produce oxygen and hydrogen. It is expensive and risky to send a continuous convoy of rockets from Earth to the Moon to keep a base supplied, which is why we need to develop the technologies that can purify the water that is already on the Moon.

The lunar environment is unforgiving. With no atmosphere and parts of the surface having never seen sunlight, the ice in the soil is as hard as steel and heavily contaminated with lunar dust - known as regolith - which forms a grinding paste when wet. It is no small feat to melt the ice, separate it from the dust and other elements and make it usable. The technologies being developed must have minimal maintenance they cannot rely on components being sent up from Earth and it wont be possible for astronauts to regularly change filters and tighten nuts and bolts.

The finalists include:

-

Titania-Diamond Annular Reactor (TiDAR) developed by Nascent Semiconductor Ltd, County Durham. The compact system employs a combination of UV light from LEDs to activate a titania catalyst and robust diamond electrodes, which are durable enough to endure the abrasive lunar soil and the G-forces experienced during launch. This combined system rapidly breaks down harmful organic and inorganic components in the lunar soil to create safe drinking water and even useful materials, such as rocket fuel from methanol.

-

SonoChem System developed by Naicker Scientific Ltd, Gloucestershire. The SonoChem System employs a groundbreaking core technology to purify water derived from lunar ice. Harnessing powerful sound waves, it spontaneously forms millions of tiny bubbles in contaminated water. The extreme temperature and pressure created within each micro bubble generates free radicals (unstable atoms which are highly chemically reactive) which effectively removes contaminants.

-

Ganymedes Chalice developed by British Interplanetary Society, London. A solar concentrator uses a curved mirror to focus the Suns rays on an air-locked crucible where lunar ice is placed by a small, automated crane. The heat from the concentrated rays boils the ice components one by one, and the system uses different storage mechanisms and chemical processes to store each component in safe and compact forms, finally condensing pure, drinkable water at the end.

It is hoped that the technologies developed for the harsh environment of space will also be deployed on Earth, particularly in water-stressed regions and where access to clean drinking water is limited.

Holly Jamieson, executive director of Challenge Works, said:

Water purifying technologies that work in the harsh environment of space can be put to great use on Earth - autonomous technology that can operate at extreme temperatures without maintenance could be deployed in remote locations around the world. They not only have the potential to aid water extraction, but also to purify dirty water safely and efficiently. Prizes are at their best when they support multiple approaches to the same problem to progress. Its exciting that the approaches being taken by the Aqualunar finalists are all so different - it means we can advance the technologies for a range of use cases on Earth as well as on the Moon.

Research by the Aqualunar Challenge found that 62% of people believe that technologies designed for space exploration should have applications on Earth, with more than half (56%) believing that using technology in space means we can better understand our own planet and how to protect it. 86% of respondents said they would like to see technologies being developed to purify lunar water adapted for use on Earth.

UK Space Agency and Challenge Works are working in collaboration with the Canadian Space Agency (CSA) and Impact Canada to deliver the Aqualunar Challenge. CSA will announce its cohort of teams for the Canada track later today.

To find out more about the Aqualunar Challenge in the UK and learn more about the ten finalists in detail, visit aqualunarchallenge.org.uk.

The ten finalist teams will be showcased at the Farnborough Air Show at 1pm on Friday 26 July in the Space Zone Theatre.

Full list of finalists

AquaLunarPure: Supercritical Water Purification on the Moon developed by Queen Mary University of London

A reactor would first heat lunar ice to leave behind dust and rock particles, then heat it to more than 373C at 220 bars of pressure to turn it into supercritical water not a solid, a liquid or a gas, but a fourth state that appears like a thick vapour in which oxidation will remove all the contaminants in one step. Direct heating and insulation contribute to the high energy efficiency of this reactor, compared to current state of the art technologies.

Cyclic Volatile Extractor (CVE) developed by Minima Design Ltd, Suffolk

The CVE will use a novel closed chamber to heat a batch of dirty ice to liberate volatile contaminants. The volume of the chamber can be actively changed to moderate its internal pressure. By regulating the temperature and pressure, different contaminants can be vapourised, liberated, collected and concentrated in separate storage systems.

FRANK Filtered Regolith Aqua Neutralisation Kit developed by RedSpace Ltd, Aldershot/Cleethorpes/Richmond (North Yorkshire)

A three-stage approach designed to deliver a continuous flow of drinking-grade water in a lunar environment would first heat the lunar soil (regolith) sample in a sealed chamber to separate off volatile gases and leave a liquid of water, methanol and regolith fragments. The liquid is passed through a membrane to remove solid particles. The remaining liquid is distilled to separate the methanol from the water.